Semi-Automatic Inspection Machines

Semi-Automatic Inspection Machine for all types of containers, designed to transfers automatically the containers into an optimized viewing area, rotating the containers and sending conforming or defective ones into separate reject areas.

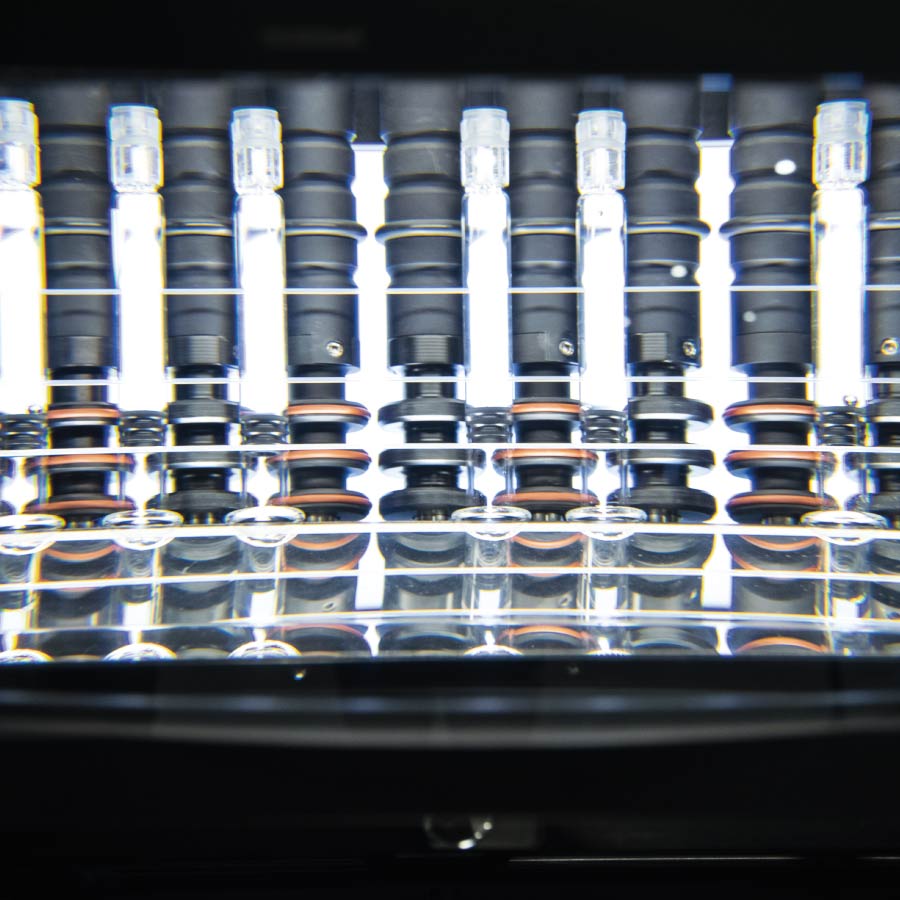

Suitable for easy and effective cosmetics and particle inspection thanks to advanced lighting patterns and backgrounds to help the operator identify defects.

Designed with a compact and modular layout to fit all products’ needs with configurable infeed: by trays, in-line or with rotary table. Denester and renester integration is available for pre-filled syringes inspection. The advanced transportation system minimises product breakage and facilitates cleaning.

For higher speed, a back-to-back dual machine configuration is available.

PRODUCTS RANGE:

- Vials, ampoules, pre-filled syringes, glass and BFS round-shaped bottles

- Liquids, powders, lyophilized products

- Empty containers

INSPECTIONS:

- Foreign matters, cosmetics, fill-level and integrity check

MULTIPLE REJECTION SYSTEMS:

- Manual: Containers classified as defective are removed manually by the operator and placed in the dedicated area. This operation can be performed without the need to stop the machine.

- Automatic: The operator points out the container to be rejected, and a dedicated LED bar is then following the container itself until reaching the rejection point, where the rejection is operated by a pneumatic device.

- Compact footprint

- Advanced lightning patterns and adjustable mirrors

- Multiple background filters

- Fast spinning for particles while slow spinning for cosmetics inspections

- Categorization of defects

- User-friendly and touchscreen interface

- Quick and easy changeover (5-10 min)