BFC Blister Filling Control

BFC, designed by Antares Vision for the inspection and correct filling of pharmaceutical blisters, is the result of the experience and the ten-year partnership between IMA, world leader in the design and production of blistering machine, and the worldwide pharmaceutical industry.

The system removes the risk of intermingling, vagrants and/or excess products, as it inspects the complete blister surface, including the part outside of the pocket. The processing power of the unit allows for an extremely accurate control, whose speed is faster than every other blistering machine available on the market: production efficiency is therefore always guaranteed.

BFC can be integrated with all classic controls along the line, TLC on the lidding foil and/or PQC (BarCode Reader and OCV/OCR) on leaflets, cartons and labels, and Box Checking for correct case-packing verification, as well as the Antares Tracking System for the production traceability.

WORKS WITH ANY KIND OF CAPSULE AND TABLET

The system can be used with all sorts of solid product such as:

- Tablets

- Capsule mono and bi-color

- Hard and soft gelatines

- Printed and embossed products

WORKS WITH ANY KIND OF SUPPORT MATERIAL

- Transparent PVC

- Colour PVC

- Opaque PVC

- Polypropylene, PVDC, alu-alu

- IImproved algorithms to manage the low contrast with white products on white PVC.

- Optimized compensation of the image in case of support deformation (chewing-gum effect).

PERFORMED CONTROLS

With intermittent or continuous motion machines the security controls performed by the BFC include:

- Counting

- Color correctness

- Geometry accuracy (area, contour, major/minor axis)

- Shape accuracy

- The detection of spots or marks

- The detection of cracks and breaks

- Mix-up, vagrant or extra products

PERFORMED CONTROLS

With intermittent or continuous motion machines the security controls performed by the BFC include:

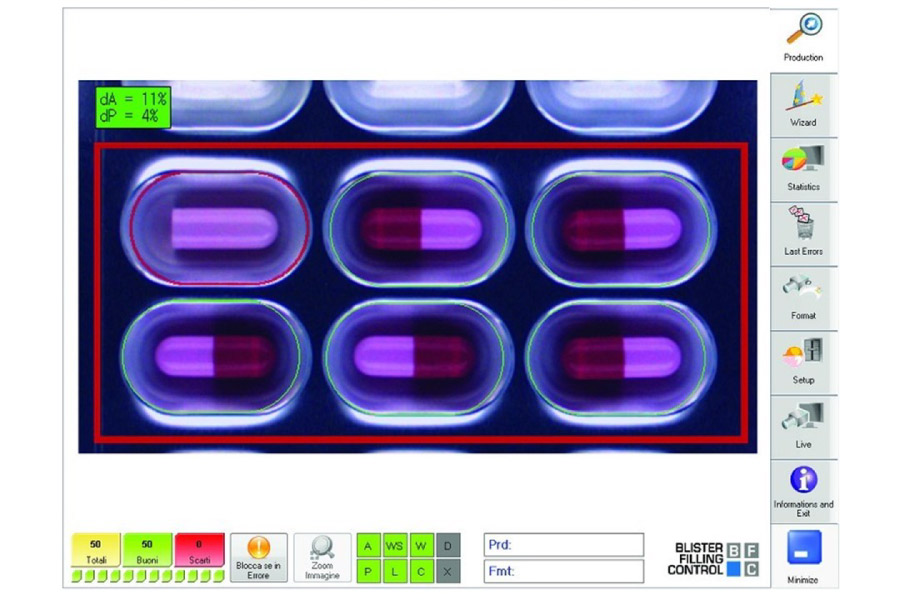

Counting Check (Presence / absence of the capsule)

![BFC Blister Filling Control [1] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a3.jpg)

Geometry Accuracy

![BFC Blister Filling Control [2] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a4.jpg)

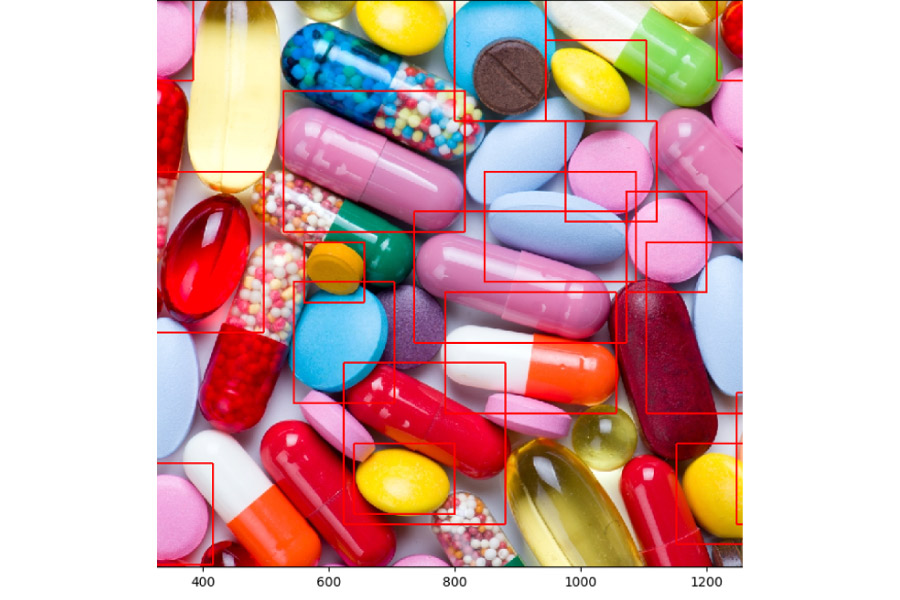

Mix-up, Vagrant or Extra Products

![BFC Blister Filling Control [3] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a5.jpg)

Shape accuracy

![BFC Blister Filling Control [4] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a6.jpg)

Chipping Check

![BFC Blister Filling Control [5] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a7.jpg)

Integrity Check (Detection of cracks and breaks)

![BFC Blister Filling Control [6] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a8.jpg)

Impurity Check (Detection of spots or marks)

![BFC Blister Filling Control [7] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a9.jpg)

Colour correctness

![BFC Blister Filling Control [8] - Antares Vision Group](https://antaresvisiongroup.com/lifescience/wp-content/uploads/sites/3/2023/01/a10.jpg)