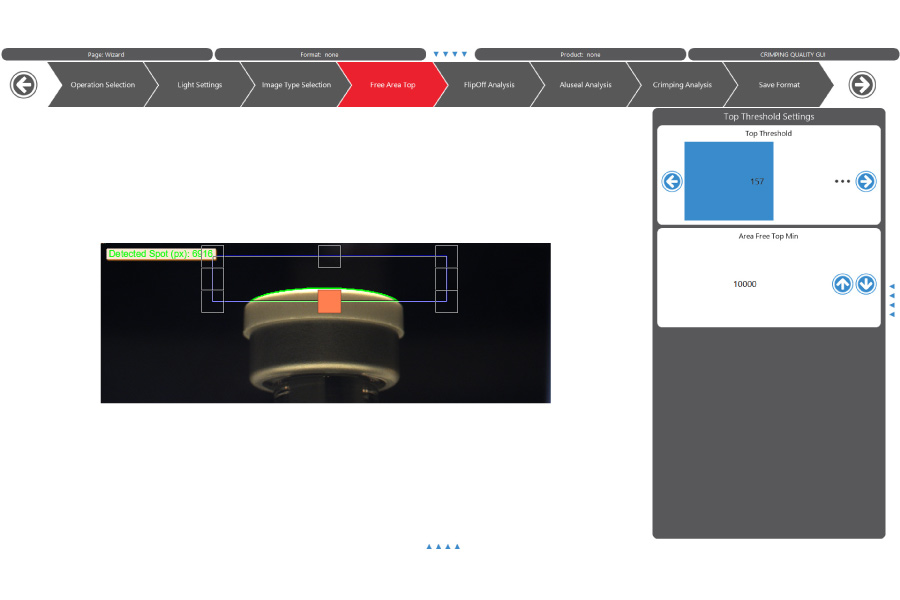

Crimping Quality Control

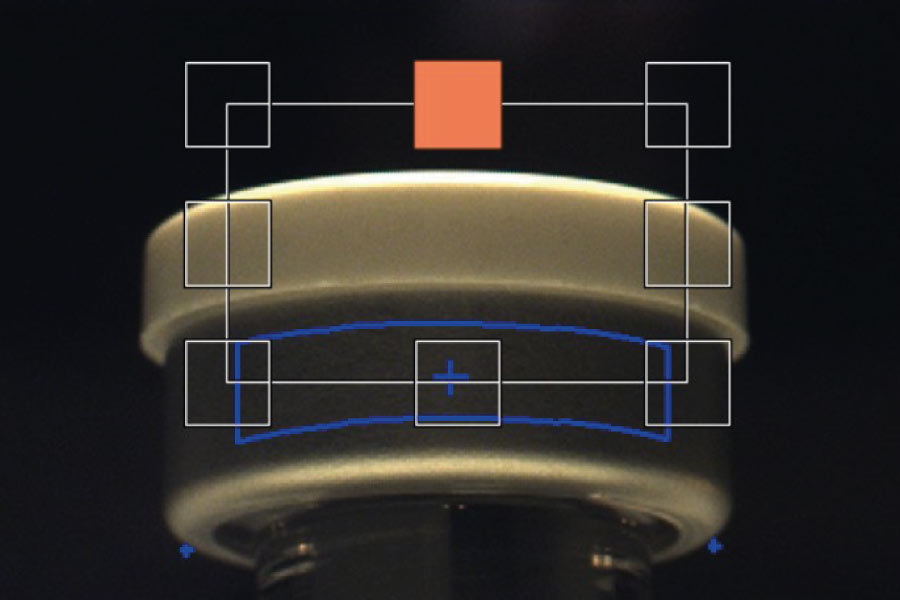

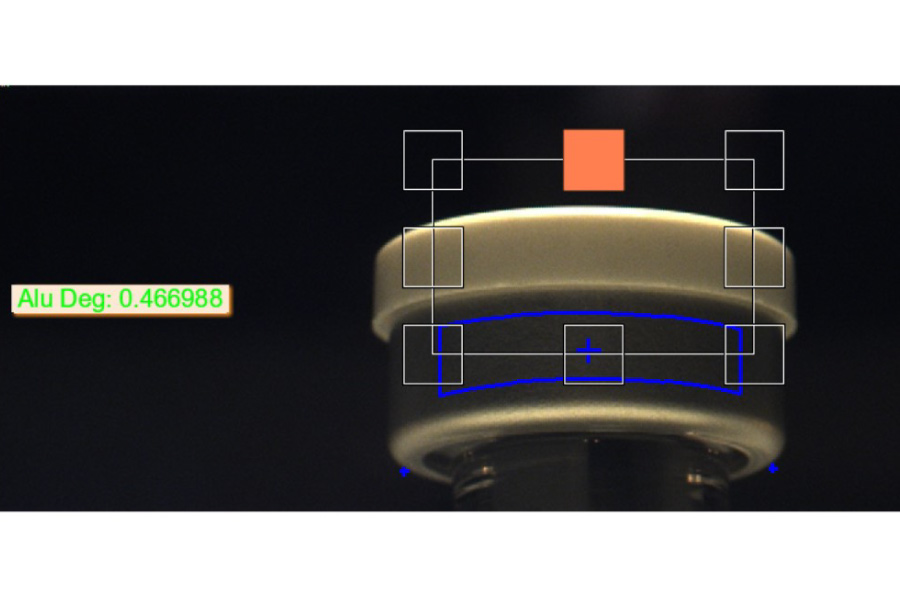

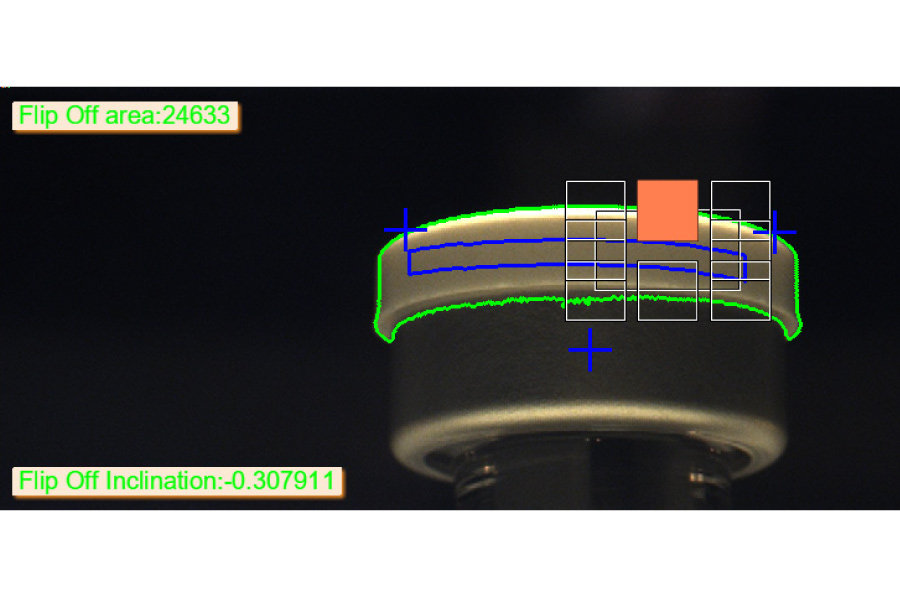

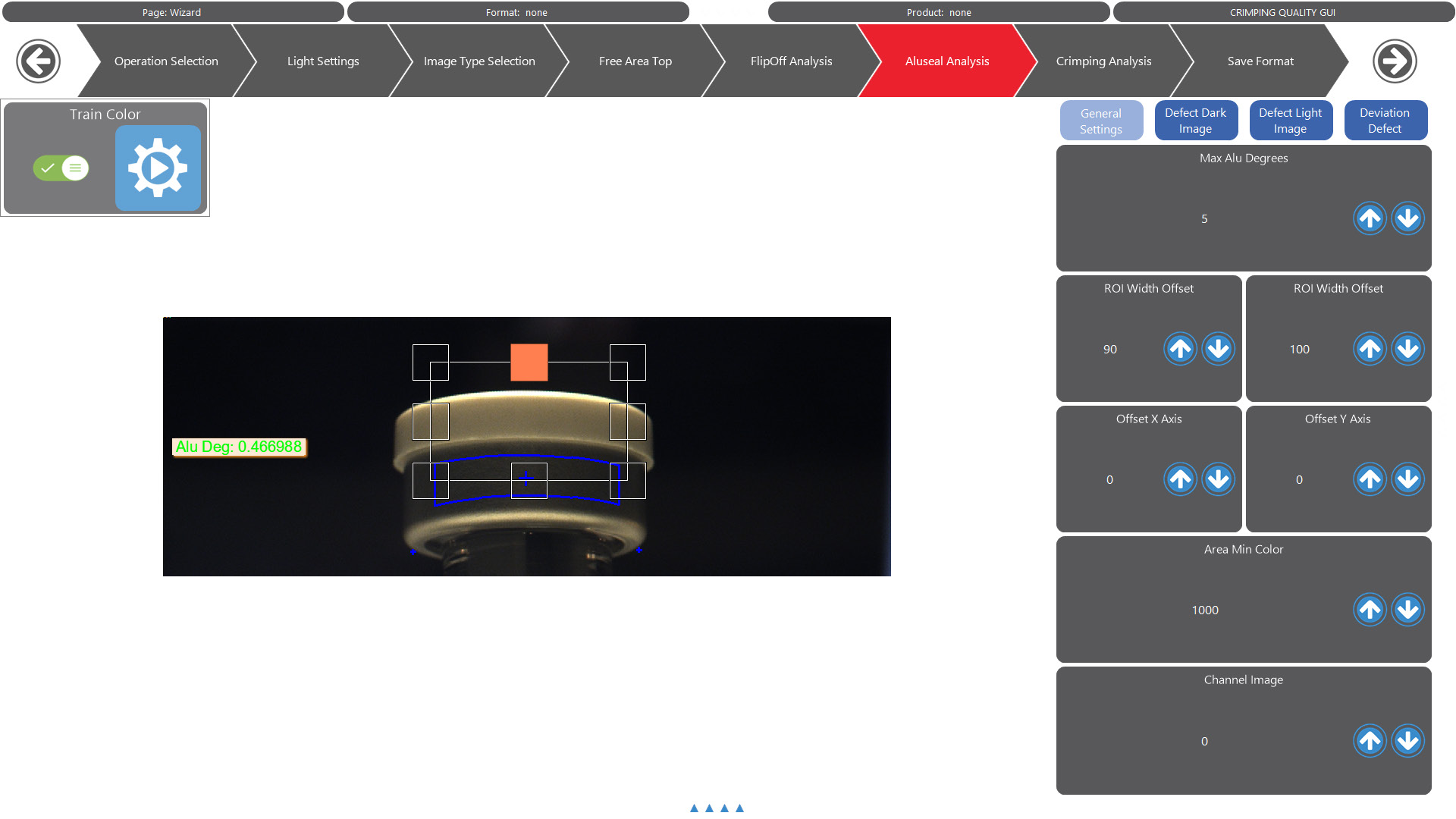

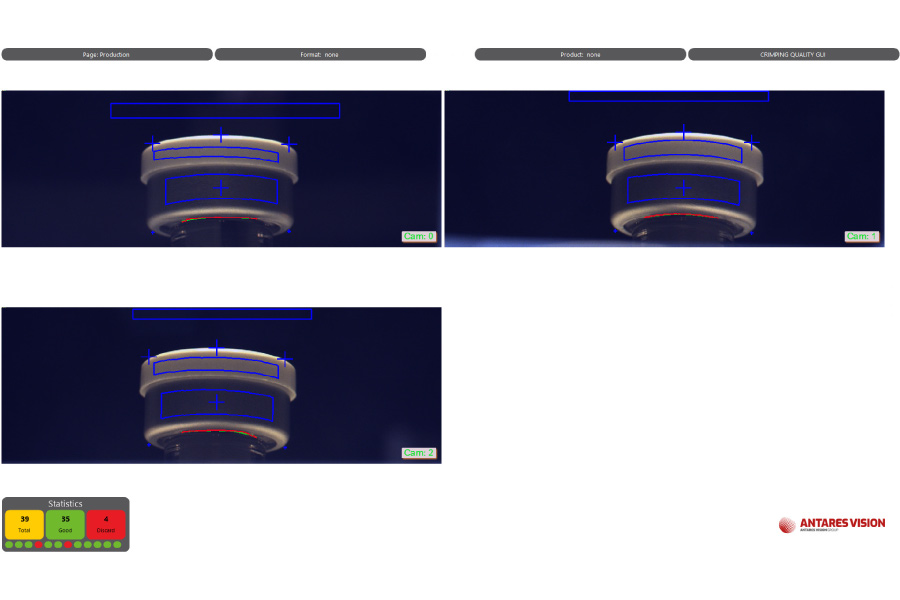

The inspection system Crimping Quality analyses vials with ring nuts. It purpose is to specifically check the integrity, quality and correctness of ring nuts and flipoffs during the sealing phase of pharmaceutical vials. The analysis is carried out by acquiring a given series of images for each vial. By processing these images the software is able to isolate the crimping and flipoff area so as to check its correctness.

Controls carried out:

- Flip off check

- Crimping quality

- Defects on ALU seal

The search for defects on the ring nut body is based on three distinct functions:

- Defect Dark Image: the main function that identifies the defects on the underexposed image (preset1) searching for transitions coming out of a Sobel filter. If this function identifies as least one defect, the following two functions will not be applied;

- Defect Light Image: the function that identifies the defects on the overexposed image (preset0) searching for transitions coming out of a Sobel filter.

- Deviation Defect: the function that searches the defects on the overexposed image by exploiting a deviation filter.