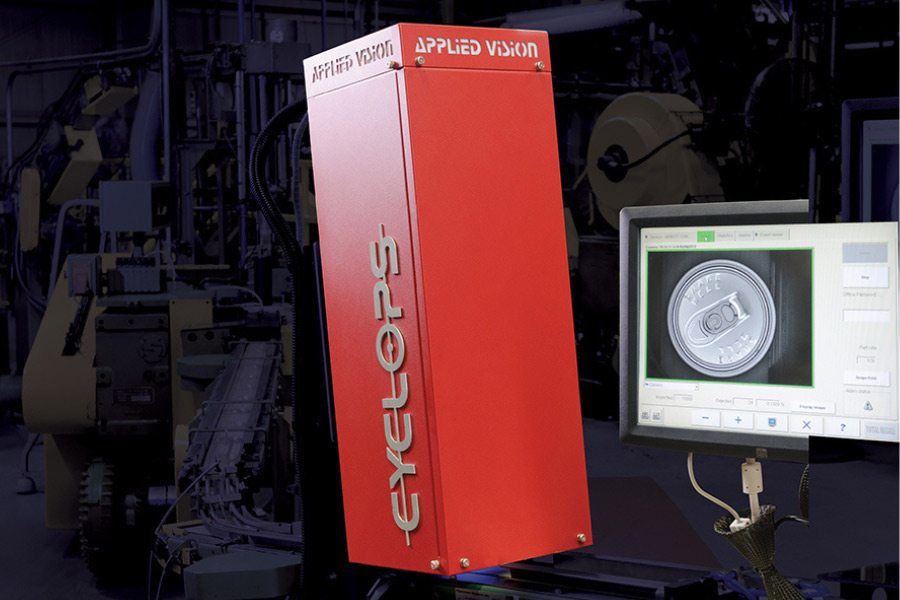

End Inspection and Seams – CYCLOPS

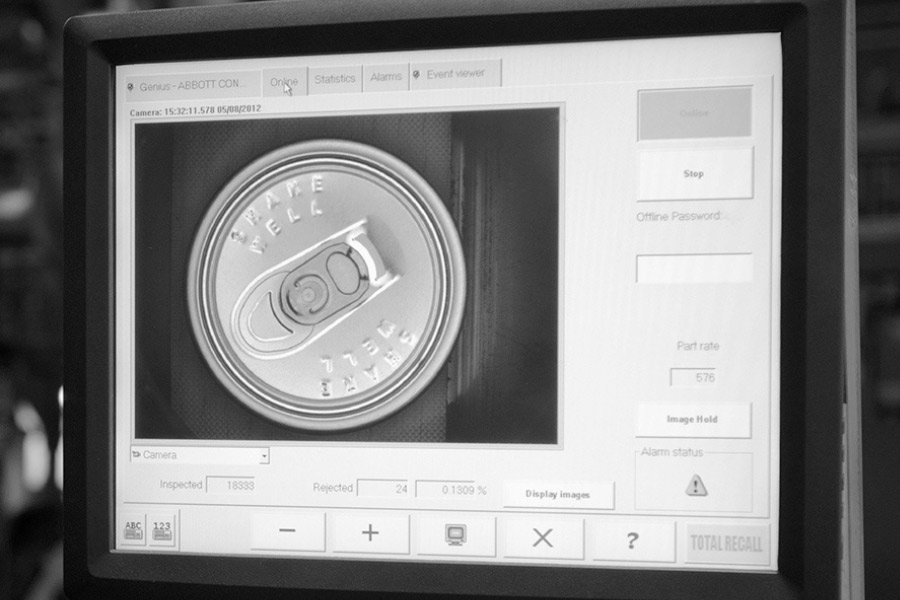

The In-line inspection system ensures the quality of food cans, performing a complete inspection of the containers. It detects weld seams, wrinkles, creases, puckers, scratches, dents, cut edge, flange, grease & oil, metal whiskers as well as powder stripes, die/draw marks, foreign objects and rivets.

With Cyclops® , you no longer need to run multiple cameras on a single processor. Each camera is self-contained with its own processor and housing, making multi-lane installations more affordable, easier to install and simpler to maintain. By combining lighting and processing into a single enclosure, the proven technology of Applied Vision can now be brought to you more efficiently and effectively.

CyclopsTM comes standard with motorized height adjustment to preprogram various container heights to run on the same line. A second camera is an option dedicated to a special inspection like rivet.

- Network access

- Flexible optical configuration to accommodate product heights from 0.1” to 8”

- Integrated eight channel solid-state lighting

- Exclusive DoubleTake technology (optional)

- Digital Gig-E camera technology

- Weld seams, wrinkles, creases, puckers, scratches

- Dents, cut edge, flange, grease & oil

- Metal whiskers as well as powder stripes

- Die/draw marks and foreign objects